RUVIMAT BA 12 type Т is a one- layer , not – reinforced polymeric membrane based on high quality plastisized PVC

Application

Waterproofing of groundwater when laying the foundations of buildings , for tunnels and other underground facilities. Prevent the passage of water under hydrostatic pressure from the soil to the interior of the building.

Characteristics – advantages

- Water tightness

- Excellent resistance to aggressive substances naturally contained in the soil and the groundwater

- High resistance to mechanical influence / tearing , piercing /

- Resistance to micro-organisms and roots penetration

- Resistance to aging

- High strength characteristics and elasticity

- Very good flexibility at low temperatures

- Easy , fast and safe installation

- High steam permeabilit

- Product suitable for reprocessing

- Excellent welding including at low temperatures

- Long service use life

Indicators / Standards

RUVIMAT BA 12 type Т is produced in compliance with БДС EN 13967: 2012 for moisture insulation of buildings , including underground parts of buildings.

Class F acc. European classification for reaction to fire EN 13501-1.

Appearance/Color

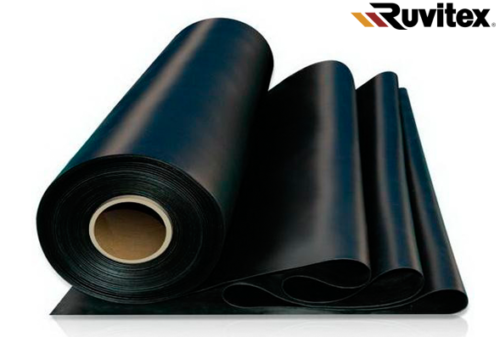

Rolled sheet membrane , homogeneous

Surface: smooth , matt

Color – black – for waterproofing of basements

– signal – for waterproofing of tunnels

Membrane with a signal color is produced on request at a minimum order quantity of 4000 m²

Packing

Each roll is packed in clear LDPE film

Roll length: 20 m

Roll width: 2 m

Roll weight: 75,00 кg

Rolls on the pallet: 21 rolls

Storing

Rolls must be stored in horizontal direction on the pallets in the original packing without direct exposure to sunlight, rain and snow. Storage following these rules guarantees no expiry date.

Concrete or old facings :

The surface of the base must be firm , smooth , without sharp protrusions, clean and dry, free of oils , paint, dust etc .

Soil :

The earthwork should be tight and the available stones and sharp objects to be removed from the surface.

Before the membranes application is placed a subject layer of geotextile .

APPLICATION LIMITS

Temperature

Temperature of the foundation : minimum 0 C / maximum +35 ° C

Temperature of the air : minimum +5 ° C / maximum +35 ° C

Compatibility

It is not allowable direct contact with the polymers of other groups, such as polystyrene, polyurethane, polyisocyanate, phenol containing foam.

The membrane is not resistant to bituminous materials , grease, tar , oils , solvents . If it is in contact with such surfaces , has to be used a separation layer of geotextile with a density of min.300g / m² , in order to be preventable the accelerated aging.

Installation Instructions

Technology of the installation : In compliance with the existing Installation manual for roofing membrane Ruvimat

Method of attachment : Free laying with a mechanical fixing or free laying with ballast

Technology of the welding : The overlaps ( from 80 to 100 mm) of the membrane must be welded by electric tools with hot air, hand held heat gun and roller or welding automatic tools with hot air, that have indiviul setting and control of welding temperature with a capacity of minimum +600°С.

The welds are carried out with a double welding seam providing a chamber for testing the weld.

Recommended mode for the equipment :

Welding parameters – The parameters of the welding process include temperature, welding speed, air stream, pressure must be chosen and checked according the weather conditions and the type of welding tools on the building area right before the welding process starts. The width of the joint must be at least 30 mm. Quality control of the welding joint is carried out by applying a pressure in the chamber between the welding joints .

Application limits

The application of PVC membrane RUVIMAT BA 12 must be performed by people that have passed a training course .

The membrane is not UV stabilized and should not be applied to open areas under the influence of sunlight.

HEALTH AND SAFETY INFORMATION

RUVIMAT ВА12 is an article within the meaning of Regulation (EC) 1907/2006 Article 3.3. A Material Safety Data Sheet following EC- Regulation 1907/2006, Article 31 is not required for the product when sold, shipped or used. The product has no harmful effects on environment and human health when stored and used as specified.

REACH

Regulation of the EU on chemicals and their safe use ЕО 1907/2006 /REACH/

RUVIMAT ВА 12 is an article within the meaning of Regulation (EC) No 1907/2006.The product does not contain any substances intended to be released from it under normal conditions of storage, use and service. Therefore, there are no registration requirements for substances in the article within the meaning of Article 7(1) of the Regulation.

Safety

Ventilation and fresh air intake must be ensured when welding of article is performed in closed rooms.

Local safety precautions must be observed !

Class of Transportation

RUVIMAT ВА12 is not classified as hazardous for transportation.

Disposal of Residual Waste

Residual waste generated from the use of the product as well as from the roll packaging is recyclable. Disposal must be according to regional and national regulations and EU legislation.